Post-Tensioned Concrete | 7 Benefits that Boost the Future of Construction

Post-tensioned concrete system - a revolutionary technology in modern construction and its applications in Saudi Arabia

System Post-tensioned concrete Post-Tensioned Concrete (PTC) is an advanced technology that has revolutionized the construction industry, combining structural strength, economic efficiency, and design flexibility. Since its first appearance in France in 1933, this system has become a preferred choice in major projects around the world, including Saudi Arabia, which has seen an increasing use of it in recent years. In this article, we will review in detail how this system works, its advantages, its applications in Saudi Arabia, and its role in supporting Vision 2030.

Overview of Post-Tensioned Concrete Technology

Post-tensioned concrete system definition

Post-tensioned concrete An advanced type of reinforced concrete in which tensile forces are applied to steel cables or tendons after the concrete has been poured and hardened. This process enhances the concrete's ability to withstand high loads, minimizes cracks, and increases the durability of the structure. The cables are tensioned using specialized equipment, which compresses the concrete and makes it more resistant to tensile and bending stresses.

History of the development of post-tensioned concrete technology

The technology began in the early 20th century, first used in France in 1933 to fulfill the need for more durable and efficient structures. After World War II, the demand for fast and efficient construction techniques for city reconstruction increased, leading to the popularization of post-tensioned concrete in Europe and America. During the 20th century, the materials and equipment used, such as high-strength steel tendons and injection systems, evolved, making this system more efficient and cost-effective.

Difference between post-tensioned and pre-tensioned concrete

Post-tensioned concrete differs from Prestressed concrete in the timing of the application of stresses:

- Post-tensioned concrete: Cables are tensioned after the concrete has been poured and hardened, making them ideal for large projects such as bridges and towers.

- Prestressed concrete: Tendons are tensioned before concrete is poured, and are often used in the manufacture of prefabricated concrete elements such as columns or beams.

| Characteristics | Post-tensioned concrete | Prestressed concrete |

|---|---|---|

| Timing of stress application | After the concrete has hardened | Before pouring concrete |

| Use | Large infrastructure projects (bridges, towers) | Prefabricated concrete elements (vines, columns) |

| Elasticity | Highly flexible in design | Relatively limited flexibility |

How the post-tensioned concrete system works

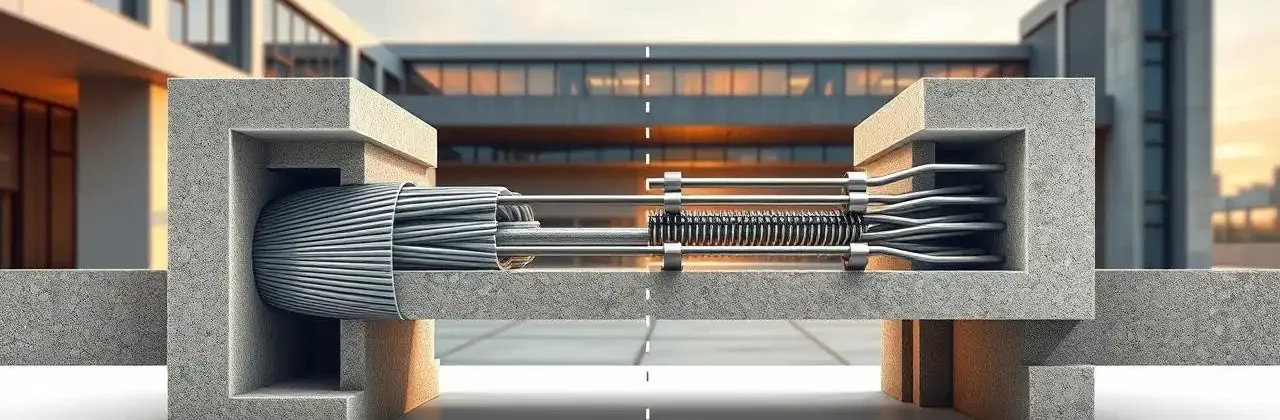

The main components of the PostTension system

The post-tensioned concrete system consists of several key components that ensure the success of the process:

- Steel cables or tendons: Made of high-strength steel to provide the necessary tensile strength.

- Bearing Plates: Supports cables and distributes stresses to the concrete.

- Ducts: Tubes that contain the cables and protect them from corrosion.

- Grouting Tubes: Used to inject filler material (grout) to bond cables to concrete.

- Anchor Head and Wedges: Fix the cables after tensioning.

- The main railroad network: Reinforces the concrete structure.

- End Bulbs: Used in some designs to distribute stresses.

Stages of post-tensioned concrete implementation

- Engineering design: Cable locations and specifications are determined based on expected loads.

- Cable and pipe installation: The cables are placed inside the pipes before the concrete is poured.

- Pouring concrete: Concrete is poured and allowed to set until it reaches the desired strength (typically 70-80% of its maximum strength).

- Cable tension: Specialized hydraulics are used to tension the cables to the specified stress.

- Grout injection: The filler is injected into the pipes to bond the cables to the concrete and protect them from corrosion.

- Final check: Ensure structural integrity and accuracy of execution.

The role of steel cables and tendons

Steel cables are the core element of this system, providing the tensile strength needed to reinforce the structure. They are manufactured from High-Strength Steel to ensure they can withstand high stresses without stretching or breaking. These cables are securely fastened with a clamp and zipper to ensure long-term stability of the structure.

| Ingredient | Functionality |

|---|---|

| Cables | Provide tensile strength to reinforce the structure |

| Chairs | Cable support and stress distribution |

| Injection tubes | Injecting filler to protect cables |

| Cast and zipper | Stabilizing the cables after tensioning |

Types and classifications of post-tensioned concrete

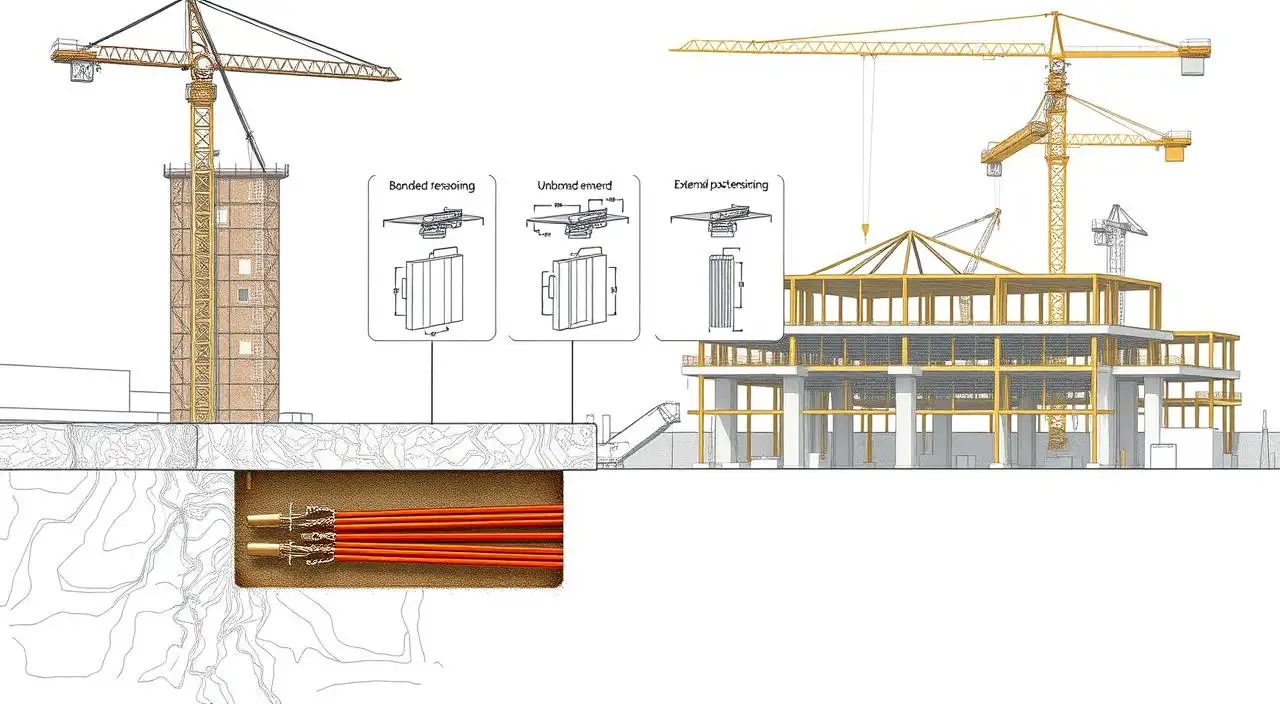

There are two main types of this system:

Bonded post-tensioned concrete

In this type, the cables are injected into pipes with grout after tensioning, fully bonding the cables to the concrete. This design provides additional protection against corrosion, enhances structural integrity, and is often used in bridges and high-rise buildings.

Unbonded post-tensioned concrete

It uses cables coated with a grease or plastic coating to facilitate their movement within the concrete. This type offers flexibility in maintenance and inspection, and is used in projects that require flexible designs, such as roofs and commercial buildings.

Single and Multiple Tensioning Systems

- Single Strand: One cable at a time, used for small or medium-sized projects.

- Multi-Strand: Multiple cables are strung together, which saves time and is used in large projects such as bridges.

| Type | Characteristics | Applications |

|---|---|---|

| Bonded | High grip, corrosion protection | Bridges, high-rise buildings |

| Unbonded | Flexible maintenance, easy inspection | Roofing, Commercial Buildings |

| Single/Multi Tension | Speed of execution (multiple), accuracy in small projects (single) | Miscellaneous projects |

Features and benefits of using post-tensioned concrete

Structural and structural benefits

- Optimized structural strength: Steel cables increase the structure's ability to withstand heavy loads and stresses.

- Earthquake resistance: Post-tensioned concrete minimizes the impact of vibrations, making it ideal for earthquake-prone areas.

- Reduce the thickness of the tiles: Allows for the design of thinner slabs and ceilings, maximizing usable space.

Economic benefits and material savings

- Minimize the amount of material: Reduces the need for traditional concrete and steel, which Reducing costs.

- Saving on foundations: Lighter structures require less complex foundations.

- Accelerating the construction process: Rapid implementation reduces labor and equipment costs.

Crack resistance and longevity

- Reducing cracks: Prestressing prevents the formation of cracks under loads.

- Long lifespan: Corrosion protection and reduced maintenance extend the life of the structure.

Flexibility in architectural design

- Enables the design of complex and innovative structures, such as long span roofs without center columns.

- Supports architectural creativity, making buildings more attractive and functional.

Comparison of post-tensioned and conventional reinforced concrete

Structural and structural differences

- Post-tensioned concrete: Reduces cracks and requires less reinforcement than traditional concrete.

- Traditional Reinforced Concrete: It relies heavily on steel rods to carry the tension, which increases the weight of the structure.

Comparison of cost and return on investment

- Post-tensioned concrete: The initial cost is higher due to specialized equipment, but it provides long-term returns by reducing maintenance and increasing lifespan.

- Traditional Reinforced Concrete: Lower initial cost, but requires more frequent maintenance and materials.

Optimal use cases for each type

- Post-tensioned concrete: Ideal for large projects such as bridges, towers, and buildings with long spans.

- Traditional Reinforced Concrete: Suitable for small projects or those that require standardized designs.

| Criterion | Post-tensioned concrete | Traditional Reinforced Concrete |

|---|---|---|

| Resistance to cracks | very high | Medium |

| Slab fish | Thinner | Thicker |

| Initial cost | High | low |

| Lifespan | Longer | Relatively shorter |

Post-tensioned concrete applications in projects in Saudi Arabia

High-rise buildings and towers

In Saudi cities such as Riyadh and Jeddah, post-tensioned concrete is widely used in large companies such as Hmmm al-Aruba in the construction of commercial and residential towers. For example Jeddah Towers It utilized this system to reduce the amount of materials used and improve the quality of the structure, allowing for innovative architectural designs.

Bridges and highways

This technology is used in the construction of long bridges and highways, such as King Fahd BridgeIt has created strong structures that can withstand heavy loads while minimizing the need for regular maintenance.

Vision 2030 projects

Post-tensioned concrete plays a pivotal role in Vision 2030such as infrastructure development in Neum andKadia. These projects rely on advanced construction techniques to achieve efficiency and enhance the quality of life.

Case studies of successful projects

- Kingdom Tower (Riyadh): The Post Tension system was used to design a unique and durable structure, reducing costs and maximizing usable space.

- Jeddah Towers: The system minimized materials and promoted sustainability.

- King Fahd Bridge: Deliver a strong and durable structure with low maintenance costs.

| Project | Application | Benefits |

|---|---|---|

| Jeddah Towers | Commercial and residential towers | Material Saving, Innovative Designs |

| King Fahd Bridge | Building long bridges | High durability, low maintenance |

| Kingdom Tower | High-rise towers | Unique design, maximize space |

Conclusion

is a Post-tensioned concrete A revolutionary technology in modern construction, providing high structural strength, crack resistance, and design flexibility, while minimizing long-term costs. In Saudi Arabia, the technology has become a mainstay in major infrastructure projects, including towers, bridges, and Vision 2030. Compared to traditional reinforced concrete, post-tensioned concrete offers economic efficiency and environmental sustainability, making it the perfect choice for the future.

Post-Tensioned Concrete FAQs

What is post-tensioned concrete?

Post-tensioned concrete is a construction technique. It uses tensioned steel cables. This increases the strength of the concrete against compression and tension.

How does post-tensioned concrete differ from pre-tensioned concrete?

In post-tensioned concrete, the cables are tensioned after the concrete is poured. In pre-tensioned concrete, the cables are tensioned before the concrete is poured.

What are the advantages of using post-tensioned concrete?

Post-tensioned concrete improves the resistance of structures to earthquakes, minimizes cracks and increases the life span of buildings.

What are the types of post-tensioned concrete?

There are two main types: Bonded and Unbonded and each type has its own advantages.

How is post-tensioned concrete technology applied in construction projects?

Steel cables are stretched inside the concrete after it is poured. This increases their strength.

What are the benefits of using post-tensioned concrete in Vision 2030 projects?

Provides many benefits for Vision 2030 projects. Improves the quality of infrastructure and increases construction efficiency.

How does post-tensioned concrete compare to traditional reinforced concrete?

Post-tensioned concrete is more resistant to stresses and strains. Minimizes cracks.

What are the applications of post-tensioned concrete in Saudi Arabia?

Used in projects such as high-rise buildings, bridges, and highways. In Saudi Arabia.