5 Steps to Implement Post Tensioning Slab Post Tensioning with Post-Tensioned Weirs

Introduction to PostTension

is PostTension System (Post-tensioning is one of the latest and most important construction systems in the world of contracting and civil engineering, especially when implementing Post Tension Slab in large projects with large seas. This system relies on the use of Post-tensioned filaments Inside Post-tensioned concrete This provides advanced engineering solutions that achieve durability, reduce costs and weight, while speeding up implementation and increasing the efficiency of construction performance.

Advantages of Post Tension in Concrete Slabs

Adoption PostTension System In the implementation of concrete slabs provides many engineering and economic advantages, most notably:

- Reduce the proportion of conventional rebar where the slab relies mainly on the tensile strength generated by the weirs.

- Reducing the thickness of concrete slabs compared to conventional systems, especially in large seas, leading to a reduction in the amount of Post-tensioned concrete used in the ceiling.

- Lighten the weight of the roof which reflects positively on the overall loads of the building and foundations.

- Accelerating the pace of implementation And the quick removal of wood screws, which reduces project duration and increases labor efficiency.

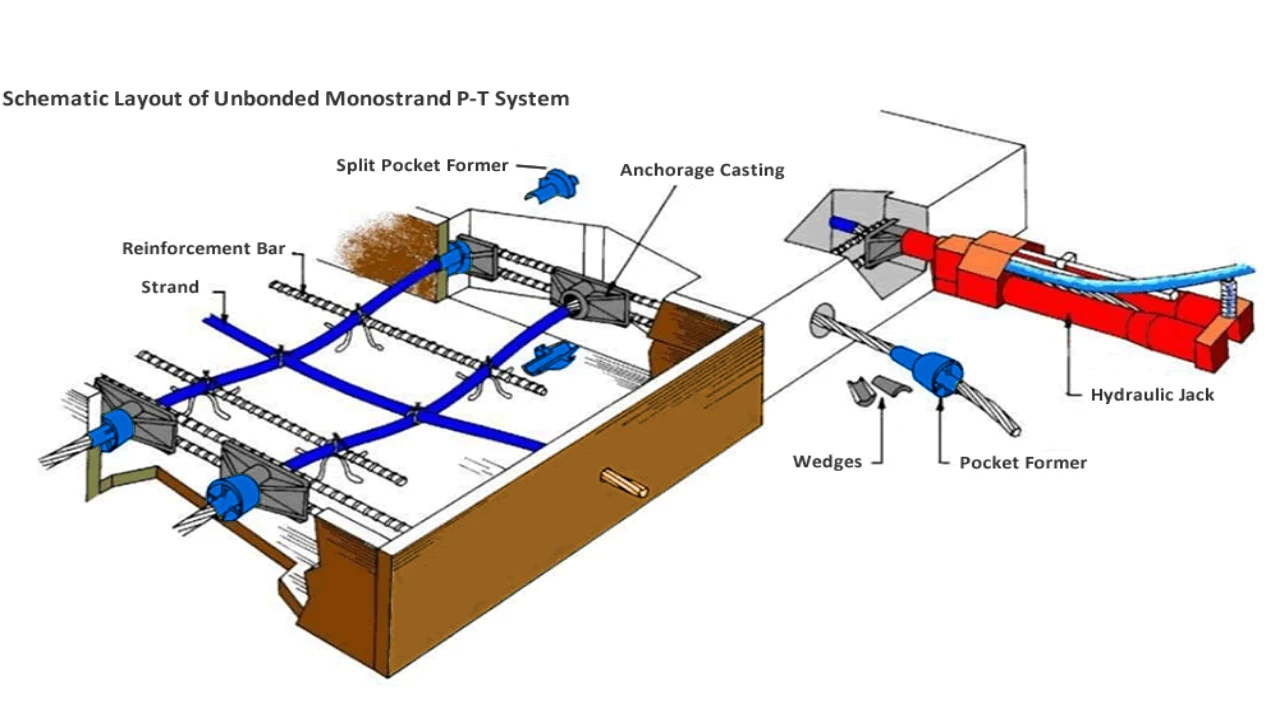

Components of the PostTension system

consists of PostTension System It consists of a set of interconnected elements that ensure the highest structural performance and structural integrity:

1. Post-tensioned Strands

is a Post-tensioned filaments The centerpiece of the system, these are high-strength steel wires, often made of nickel, with each strand consisting of seven strands. Available in 0.5-inch and 0.6-inch diameters, prices are based on diameter.

2. Dead End

Known as the "bulb," it is the end of the weir assembly, which is secured within a single duct by an iron skewer.

3. Live End

It is called a "cast," through which the weirs are stretched after casting the Post-tensioned concrete and cracking the concrete cubes. The length of the weir should be about 40-50 cm longer than the end of the roof to facilitate tensioning. In large seas (more than 30 meters), the weirs are tensioned on both sides.

4. Ducts

Metal or plastic sleeves to protect the weirs from entering the concrete, supplied in lengths of 4-5 meters, and assembled on site using special joints and adhesive tape to prevent concrete leakage.

5. Chairs

Similar to traditional reinforcing chairs, there are galvanized or plain types with plastic pieces at the ends, and they are used to hold the ducts at the correct heights according to the design.

6. Zippers or zippers

These are spiral cantilevers placed at the beginning and end of each Tendon to avoid cracks or breaks in the concrete during tensioning, and are often made of 12mm steel.

7. Anchor Head

A hollow piece of metal fixed to the duct and containing holes in the number of weirs, with a piece of foam placed in front of it to facilitate cleaning and prevent the entry of concrete.

8. Wedges

It is used to stabilize the weirs after stretching and prevent them from bouncing back.

9. Injection Tubes

It is placed at the beginning and end of the duct, and is used to inject grout material after tensioning to ensure stabilization and prevent corrosion.

10. The main railroad network

These are often iron skewers to prevent shrinkage cracks, and are distributed by design.

Stages of PostTension implementation

1. Design and Material Approval Phase

- The design is made Post Tension Slab Using specialized engineering software such as Adapt or RAM, outputting detailed charts showing the distribution of tindons and profiles.

- Materials are certified through laboratory testing of hydraulic cylinders and machines, and the test results must match the design requirements.

2. Implementation stage

- Execution begins with locating and accurately positioning the chairs in the X and Y directions, then installing the ducts and attaching them to the chairs.

- Ensure that the desks and chairs are positioned according to the plates, reviewing the location of the bulb, cassette, and injection tubes.

- The top reinforcement, electrical and mechanical work is then completed, with the cables rechecked before casting.

3. Tensile stage

- After pouring Post-tensioned concrete To reach a minimum resistance of 75%-80% of design stress, the weirs are tensioned using a hydraulic jack.

- Elongation readings are recorded for each weir, and tensioning is often done at 75% of design cutting force, with re-tensioning if required.

4. Authorization and injection phase

- Tensile readings are reviewed by the design office, and elongation ratios are calculated and compared to theoretical values.

- After the results are approved, the appendages are cut and the openings are closed with a cement mortar with Grout, and the ducts are injected with Grout to ensure the protection of the wafers.

The importance of the PostTension system in Hammam Al-Orouba Contracting Company's projects

The company is committed to Humm Al-Orouba Contracting Applying best engineering practices in the implementation of PostTension System ensuring the highest quality of Post Tension Slab while minimizing costs and speeding up implementation. Our experience in dealing with Post-tensioned filaments and Post-tensioned concrete From residential towers to malls and hospitals, our clients are assured of cutting-edge solutions that meet all the requirements of modern projects.

Conclusion

The choice of PostTension System The implementation of concrete slabs represents a quantum leap in the world of contracting, providing advanced engineering and economic solutions. If you are looking for quality, speed and durability in your projects, the Post Tension Slab Using Post-tensioned filaments and Post-tensioned concrete is the perfect choice, and Hammam Al-Orouba Contracting is your ideal partner to implement these systems with high professionalism.

Frequently Asked Questions about PostTension

How does the Posttension system effectively reduce the weight of the roof?

Allows PostTension System The thickness of the concrete slabs is reduced compared to conventional systems, thanks to the distribution of the internal forces generated by the tension of the post-tensioned weirs within the post-tensioned concrete. This reduction in thickness directly leads to a reduction in the amount of concrete and steel used, thus significantly reducing the overall weight of the roof. Reducing weight is beneficial in reducing loads on columns and foundations, which has a positive impact on structural design and construction costs.

What are the common challenges during the stretching phase and how do you overcome them?

One of the biggest challenges during the tensile phase:

- Failure to reach the desired concrete stress: You should make sure that Concrete Achieved the required ratio of pre-tensioned resistance (typically 75%-80% by design).

- Move rollers or chairs during other work: This can be bypassed by reviewing the installation before tightening and making sure they are not repositioned after electrical or mechanical work.

- Cracks or damage to the concrete at the edges: This is overcome by using zippers at the beginnings and ends of the tendons.

- Elongation readings do not match the theoretical values: The results should be reviewed with the design office and re-tensioned if necessary, making sure the tensioning equipment is calibrated.

How can I be sure of the quality of the filaments before the lift?

To ensure the quality of Post-tensioned filaments You should:

- Request official test certificates from the supplier showing the Minimum Breaking Load for each batch.

- Carry out elongation tests in an accredited laboratory, using 1-meter specimens, and ensure that the test results are not less than the design values.

- Reject any batch of weirs that do not meet the required specifications, and do not use them in the project.

Why is the use of plastic buckets not preferred in some cases?

Although plastic ducts (mono system) offer flexibility in installation, they are less durable than metal ducts (aluminum or sheet metal), and can be damaged or deformed during casting or tensioning. They are also less able to resist concrete penetration and ensure full protection of the weirs, which may lead to insulation or reinforcement issues in the long run. This is why metal rollers are preferred for most Post Tension Slab projects to ensure quality and durability.

How do the design and testing phases affect implementation success?

The design and certification phases play a pivotal role in the successful implementation of PostTension System :

- Careful design using certified software ensures that forces are properly distributed and that the positions and heights of chairs and tendons are in line with loading requirements.

- Material certification after laboratory testing ensures that all components conform to technical specifications.

- Reviewing tensile test results during construction allows any technical or structural errors to be corrected immediately, increasing the quality and safety of the final concrete structure.

- Hammam Al-Orouba provides many services and strives to achieve sustainability and build a strong and cohesive society, realizing the Kingdom's Vision 2030.

1 Comment

وليد محمد

جيد جدا